Superior Quality. Increased Productivity

Through continuous investment in training, new technologies, and equipment, PaperGraph’s dual objective is ensuring high quality in output and increasing productivity, which creates a competitive advantage through flexibility and optimal delivery times.

This means that at PaperGraph, we share the same vision with our clients for reliable cooperation, quality products, high-end service, and good value for money. Thus, the outcome of our work—which serves the commercial needs of our clients—contributes to their growth. Thus, the outcome of our work—which serves the commercial needs of our clients—contributes to their growth.

Capable of printing 4 colors simultaneously on both sides of the sheet or 8 colors on one side, with a speed of 18,000 sheets/hour, 2 inline color and registration measurement systems, and the highest level of automation available in the market, creating the conditions for maximum productivity combined with the highest print quality at extremely competitive costs.

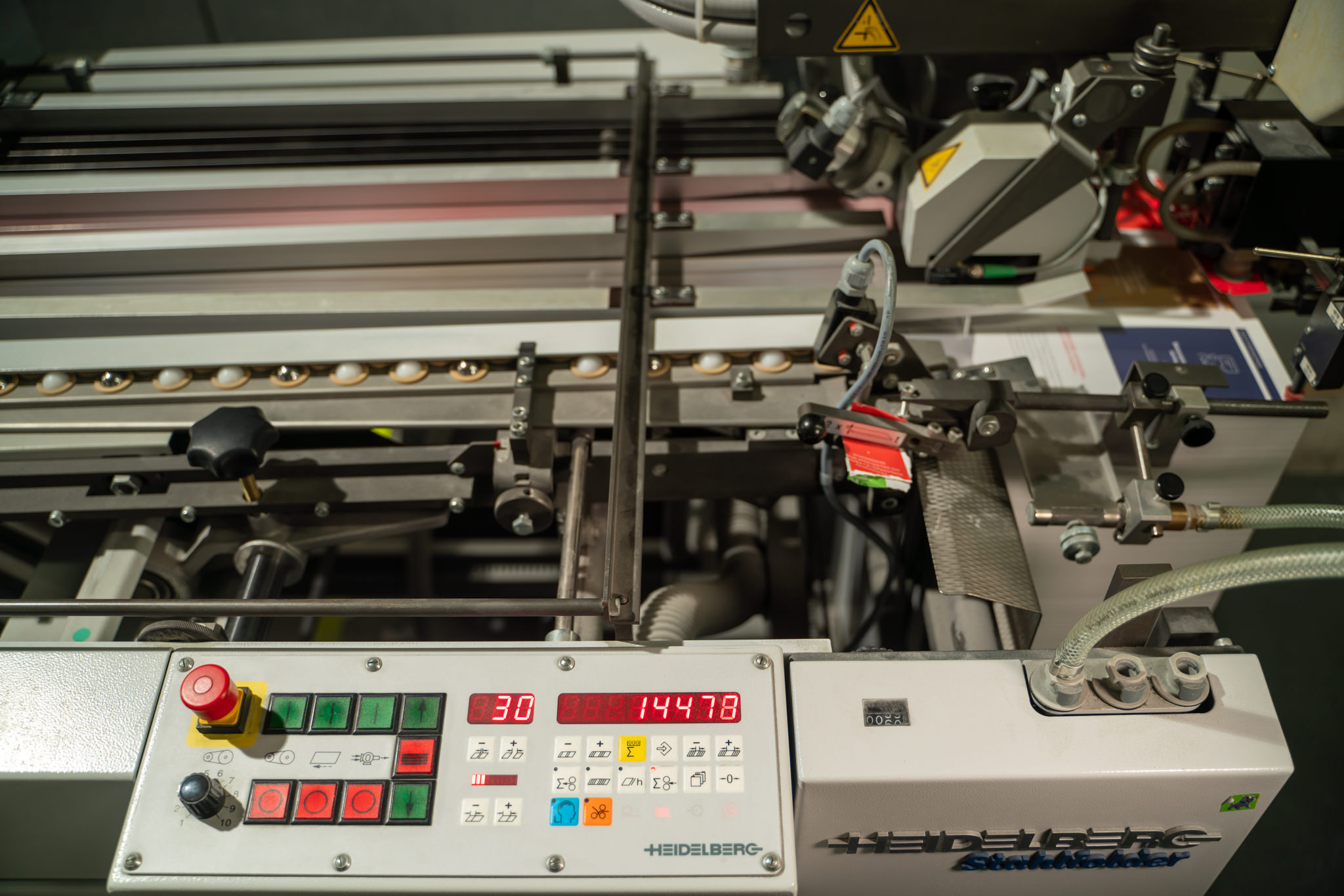

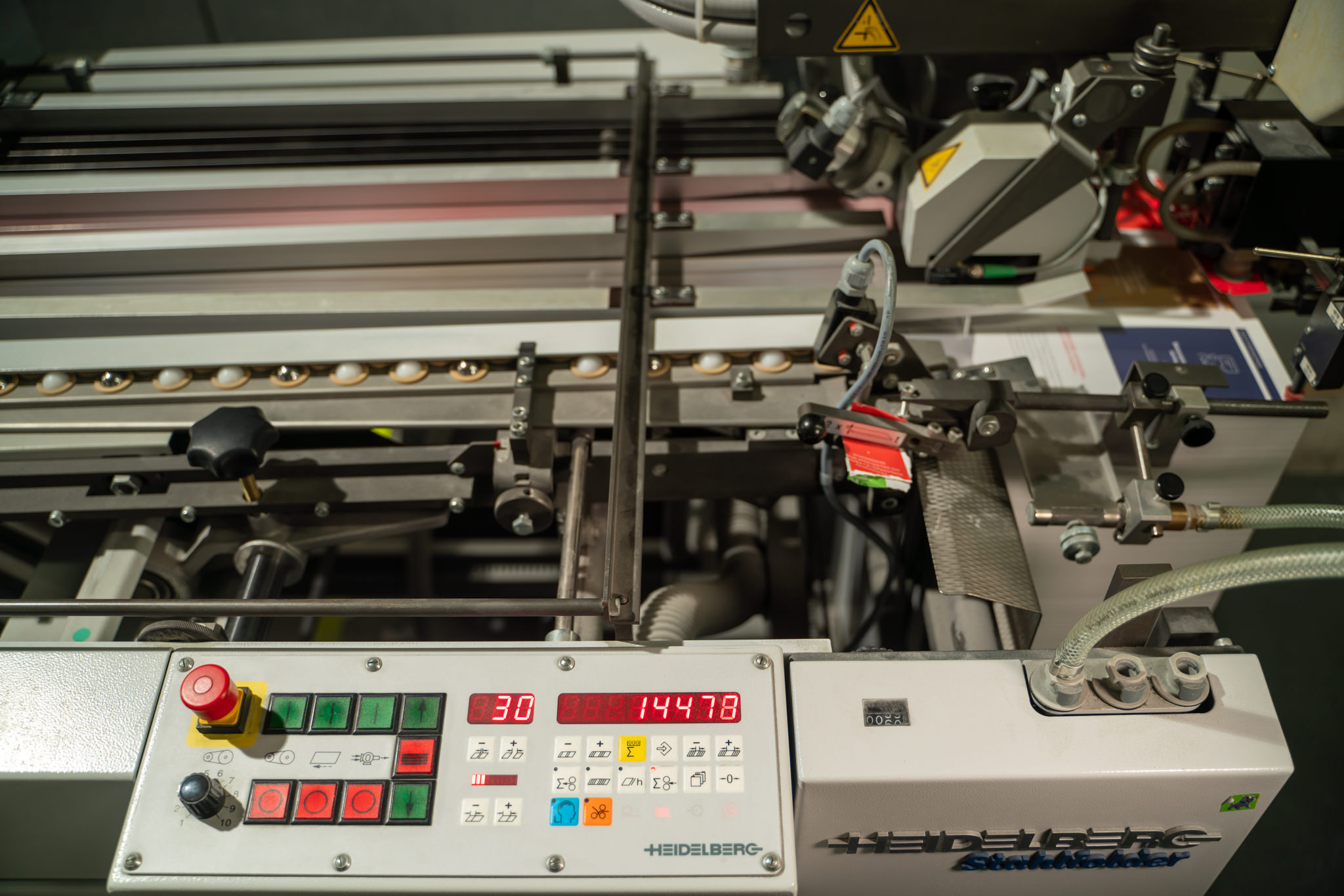

The Heidelberg CD 102-5+L features a color control and automatic correction system, prints 5 colors and water-based varnish with anilox system, at a speed of 15,000 sheets/hour and format 72×102. Paper weight from 60 g/m² up to 1 mm thickness.

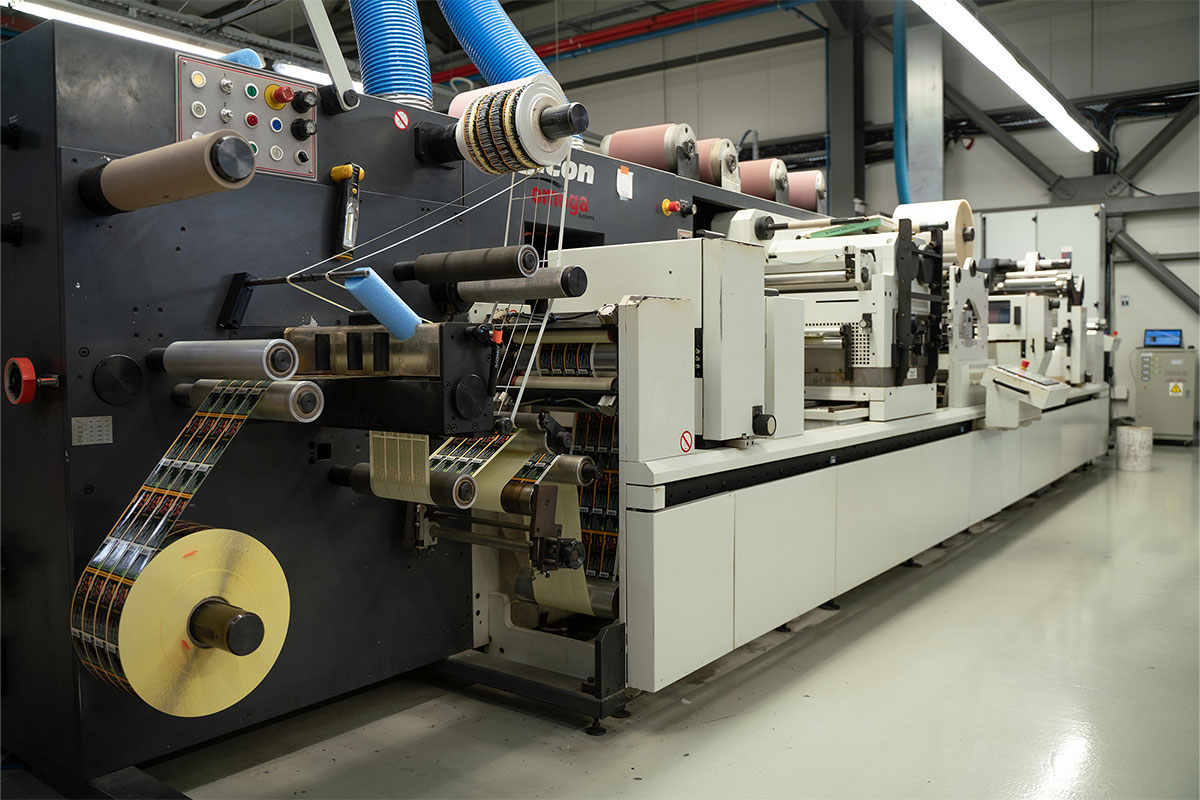

Our printing machine combines technological innovation with performance, offering a complete printing solution that meets every need.

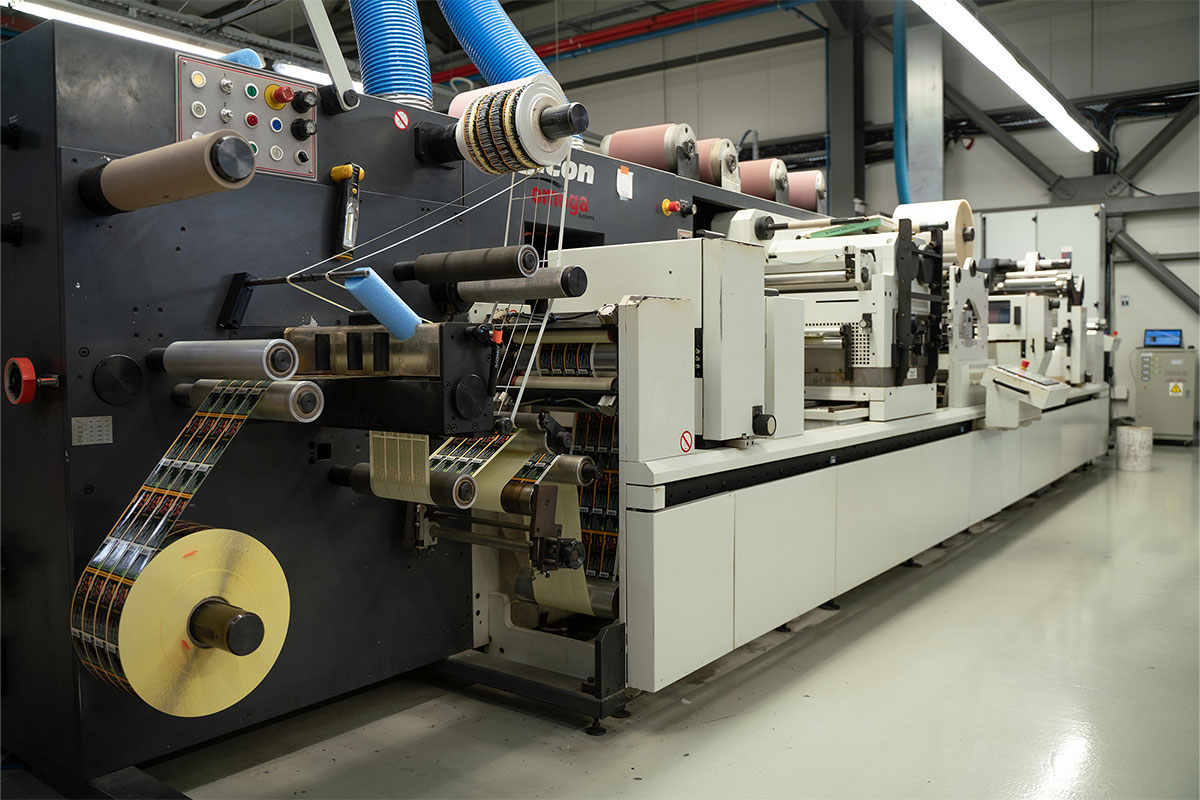

Colors are printed using offset technology, ensuring unique quality and detail, ideal for vivid and precise prints.

White ink is applied using gravure printing, providing excellent coverage and intensity, ideal for demanding applications.

At the same time, varnish is applied via flexography, offering flexibility and the ability to create impressive finishes that enhance the final product.

With production speeds exceeding 300 meters per minute, the machine ensures maximum productivity and reduces the execution time of large orders. Additionally, reduced prepress costs make this solution particularly economical, without compromising quality.

The HP Indigo Press R WS6000 7 color is a digital printing machine, specially designed for industrial label and packaging printing, using liquid electrophotography technology.

With 7 color stations, it provides the ability to produce accurate shades, even with custom colors or white ink printing, significantly expanding creative possibilities.

PaperGraph features modern finishing equipment and a wide range of services such as folding, saddle-stitch binding, sewn or glued binding, hardcover binding, die-cutting, hot stamping, UV varnish, etc.

The Muller Martini Bravo Plus Amrys is the most advanced saddle-stitch binding machine in Greece, capable of producing print materials up to 475×300 mm in size, with 7 signature feeding stations, signature inspection cameras, production speed up to 12,000 pieces per hour, among other features.

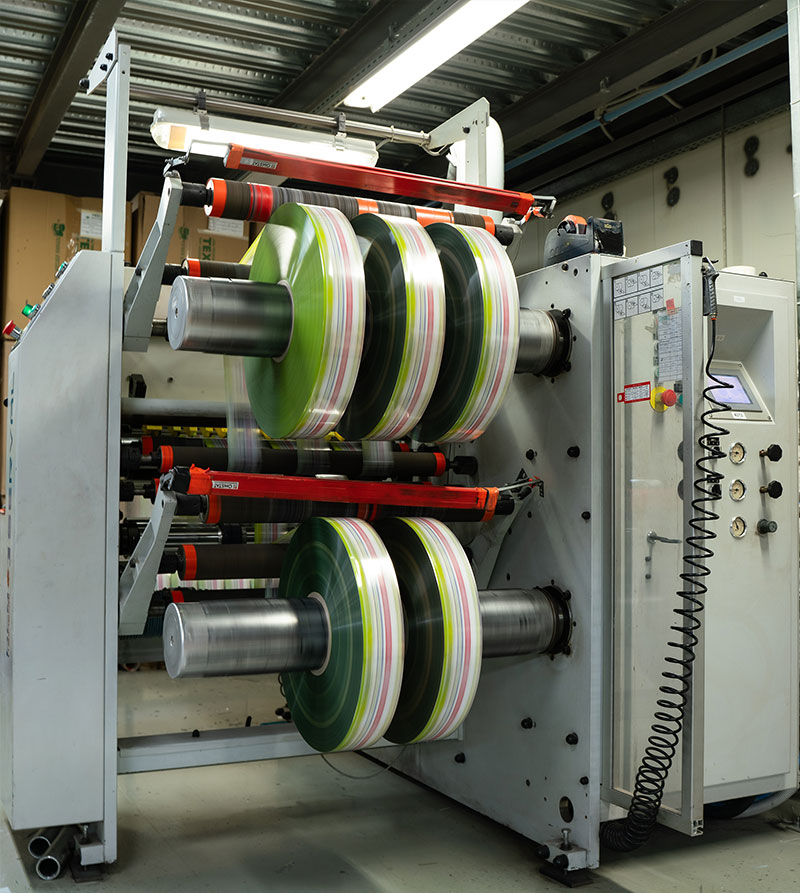

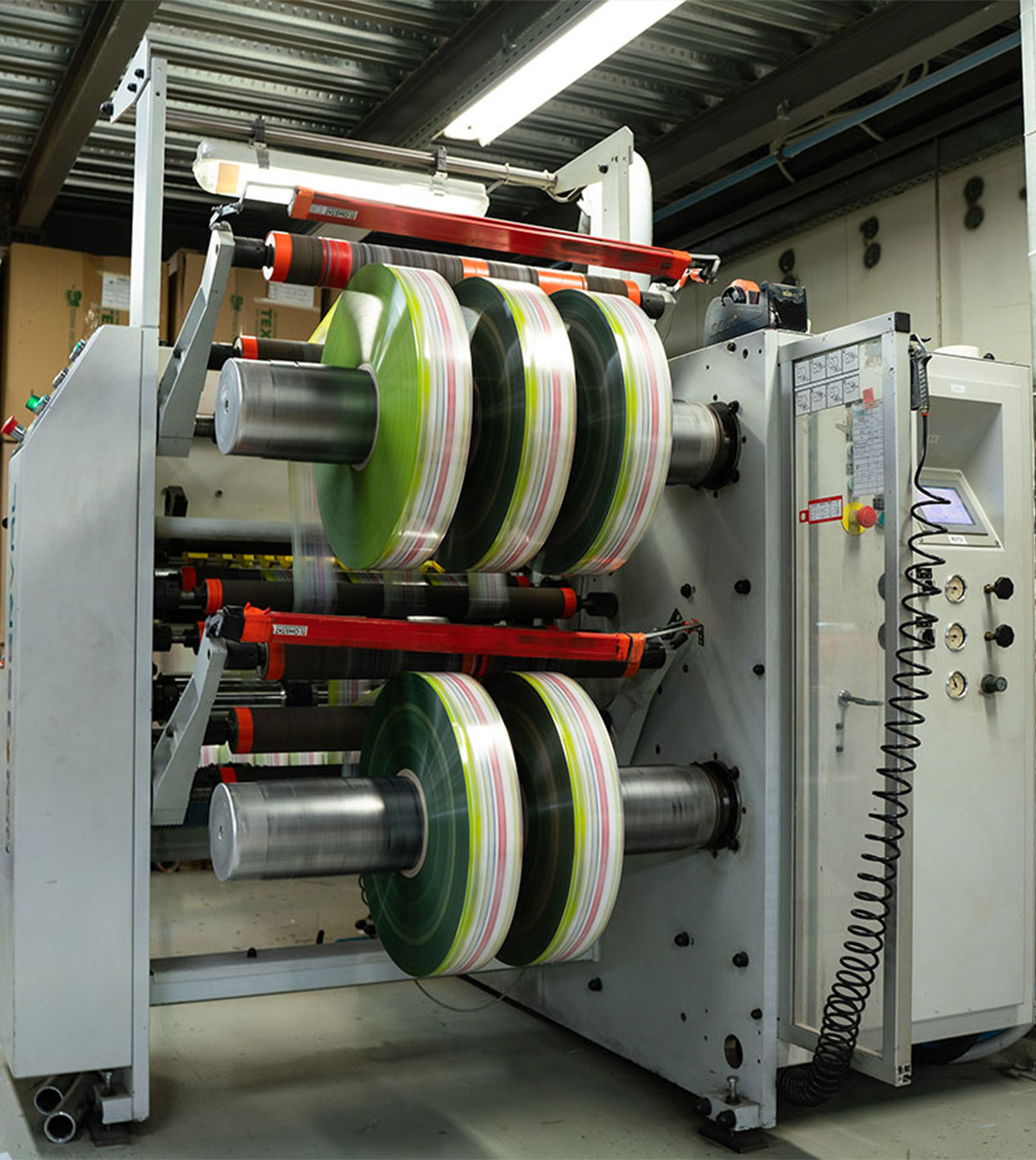

To complete the products 6 roll finishing and quality control lines.

(Technology) (2) PaperGraph combines services and machinery to (increase) productivity* and optimise the quality of its products.

Through continuous investment in training, new technologies, and equipment, PaperGraph’s dual objective is ensuring high quality in output and increasing productivity, which creates a competitive advantage through flexibility and optimal delivery times.

This means that at PaperGraph, we share the same vision with our clients for reliable cooperation, quality products, high-end service, and good value for money. Thus, the outcome of our work—which serves the commercial needs of our clients—contributes to their growth. Thus, the outcome of our work—which serves the commercial needs of our clients—contributes to their growth.

Capable of printing 4 colors simultaneously on both sides of the sheet or 8 colors on one side, with a speed of 18,000 sheets/hour, 2 inline color and registration measurement systems, and the highest level of automation available in the market, creating the conditions for maximum productivity combined with the highest print quality at extremely competitive costs.

The Heidelberg CD 102-5+L features a color control and automatic correction system, prints 5 colors and water-based varnish with anilox system, at a speed of 15,000 sheets/hour and format 72×102. Paper weight from 60 g/m² up to 1 mm thickness.

Our printing machine combines technological innovation with performance,

offering a complete printing solution that meets every need.

Colors are printed using offset technology, ensuring unique quality and detail,

ideal for vivid and precise prints.

White ink is applied using gravure printing, providing excellent coverage and

intensity, ideal for demanding applications.

At the same time, varnish is applied via flexography, offering flexibility and the

ability to create impressive finishes that enhance the final product.

With production speeds exceeding 300 meters per minute, the machine

ensures maximum productivity and reduces the execution time of large

orders.

Additionally, reduced prepress costs make this solution particularly

economical, without compromising quality.

The HP Indigo Press R WS6000 7 color is a digital printing machine, specially designed for industrial label and packaging printing, using liquid electrophotography technology.

With 7 color stations, it provides the ability to produce accurate shades, even with custom colors or white ink printing, significantly expanding creative possibilities.

PaperGraph features modern finishing equipment and a wide range of services such as folding, saddle-stitch binding, sewn or glued binding, hardcover binding, die-cutting, hot stamping, UV varnish, etc.

The Muller Martini Bravo Plus Amrys is the most advanced saddle-stitch binding machine in Greece, capable of producing print materials up to 475×300 mm in size, with 7 signature feeding stations, signature inspection cameras, production speed up to 12,000 pieces per hour, among other features.

Final Finishing and Roll Conversion

To complete the products 6 roll finishing and quality control lines.

Με το βλέμμα στραμμένο στο μέλλον, η PaperGraph εγκαινιάζει το 2025 με νέες επενδύσεις στον τομέα της παραγωγής ετικετών Wrap around, Shrink Sleeves, Booklet σε ρολό με braille ή χωρίς και εύκαμπτης συσκευασίας. Μια στρατηγική κίνηση που ενισχύει την ανταγωνιστικότητα και τη δυναμική της στην αγορά.

Εστιάζουμε στην υιοθέτηση φιλικών προς το περιβάλλον τεχνολογιών, καθώς και την ανάπτυξη ειδικευμένου προσωπικού, διασφαλίζοντας την κορυφαία ποιότητα και αξιοπιστία που χαρακτηρίζει την Papergraph εδώ και δεκαετίες.

Ανυπομονούμε να μοιραστούμε μαζί σας τη νέα αυτή εποχή για την PaperGraph και να συνεχίσουμε να χτίζουμε μαζί το μέλλον της εκτύπωσης.

With an eye on the future, PaperGraph is launching 2025 with new investments in the production of wrap-around labels, shrink sleeves, roll booklet labels with or without braille, and flexible packaging. A strategic move that enhances its competitiveness and market presence.

We focus on adopting environmentally friendly technologies as well as developing specialized personnel, ensuring the top quality and reliability that has defined PaperGraph for decades.

We look forward to sharing this new era for PaperGraph with you and continuing to build the future of printing together.